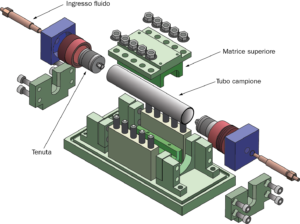

The tube hydroforming allows the manufacture of thin-walled structural components of varying cross-section along their length. This allows components to be optimized in weight and strength. As a consequence of that, the hydroformed tube is currently the most used in the transport sector. Even if it is a widely used technology, major challenges remain, in particular when dealing with new materials with reduced formability. Furthermore, the prediction of a failure in a hydroformed tube requires the use of solid elements, which hamper industrial simulations due to computational cost. In this research, they have studied the hydroforming of extruded and fully annealed tubes, in particular of aluminium 6061, using a combination of FEM analysis and experiments. Experiments were carried out on a plant customized with hydroformed tube, using extruded Al-6061-O tubes with external diameter of 60 mm and thickness of 3 mm. Experiments were simulated through Abaqus/Standard. Tubes were subjected to heat treatment, using the following procedure: tubes were heated to 415 °C and left to soak for 3 hours. Subsequently, they were cooled with a rate of 28 °C/h until they reached the temperature of 260 °C. The entire operation lasted about 9 hours. After that, the tubes were left to air-cool at environmental temperature. These samples were analysed after the heat treatment to determine the properties of the material to be used in numerical simulations. In this preliminary study, the tube failure occurred in the regions where the flat sides of the tube met the curved sides.

The tube hydroforming allows the manufacture of thin-walled structural components of varying cross-section along their length. This allows components to be optimized in weight and strength. As a consequence of that, the hydroformed tube is currently the most used in the transport sector. Even if it is a widely used technology, major challenges remain, in particular when dealing with new materials with reduced formability. Furthermore, the prediction of a failure in a hydroformed tube requires the use of solid elements, which hamper industrial simulations due to computational cost. In this research, they have studied the hydroforming of extruded and fully annealed tubes, in particular of aluminium 6061, using a combination of FEM analysis and experiments. Experiments were carried out on a plant customized with hydroformed tube, using extruded Al-6061-O tubes with external diameter of 60 mm and thickness of 3 mm. Experiments were simulated through Abaqus/Standard. Tubes were subjected to heat treatment, using the following procedure: tubes were heated to 415 °C and left to soak for 3 hours. Subsequently, they were cooled with a rate of 28 °C/h until they reached the temperature of 260 °C. The entire operation lasted about 9 hours. After that, the tubes were left to air-cool at environmental temperature. These samples were analysed after the heat treatment to determine the properties of the material to be used in numerical simulations. In this preliminary study, the tube failure occurred in the regions where the flat sides of the tube met the curved sides.

Source: Melina Kronis, Vojtech Kubec and Yannis P. Korkolis, “Hydroforming of extruded and fully-annealed 6061 aluminium tubes: experiments and analysis”, The 12th International Conference on Numerical Methods in Industrial Forming Processes – NUMIFORM 2016, University of Technology of Troyes – France, 4-7