Automation is increasingly widespread in several sectors. Applications and the world of welding are not the exception. How widespread is it and what benefits does it bring?

The market for robots is steadily growing across the world, and Italy has an excellent tradition both in terms of construction and integration of robotic automation systems in production plants. The sectors that absorb the most production and use of industrial robots are: automotive, electronics, metals, and plastics.

The inclusion of robotic islands in the Italian industrial context has changed the production cycle of many companies, increasing the quality of products and the speed of processing, thereby cutting costs and reducing safety risks for operators.

Welding and Robots: how are we doing?

The islands are usually used for handling, assembly, painting and welding.

Handling is the primary field in robotics use, with a global share of 44%, followed by welding, particularly in car manufacturing countries. In our country, handling robots account for more than half of production, while robots used in the welding sector account for 37% (spot welding, laser welding, etc.).

Robotic welding plays a key role in the automotive sector. Combined with handling and assembly operations, it is being extended to new applications in the manufacturing sector throughout the whole production cycle. Integrating a complex system means designing and manufacturing all the components and parts of the system, manipulators, tools and accessories, in tune with the technologies to be implemented such as welding, cutting or assembly.

Optimization should be extended to production flow management and industrial logistics issues, in order to guarantee cost reduction and achieving high and repeatable product quality. Today, large company procedures require production lines to adapt to continuous batch changes, aiming to constantly reduce storage and promote product customization. It is therefore essential to design and implement production lines that meet these flexibility and versatility requirements, as well as the aim of reducing storage costs and depreciation of expensive machinery.

The situation in Italy

The Italian sector has shown considerable interest in technological innovation in terms of increasing production and use of automation. This has led to a dynamic trend in foreign markets, with a high percentage of robot sales and automated systems. Italy is in sixth place in the market ranking for new robotic installations in the industrial sector. Indeed, in 2017 consumption increased by 8% compared to the previous year. According to data provided by SIRI (Italian Association of Robotics) and IFR (International Federation of Robotics), 9,237 new robots were installed in 2018, with an expected increase of 5% in 2019, thanks to the incentives provided by the National Industry Plan 4.0. Between 2008 and 2018, the number of imported robots increased by an average of 11.2% per year with finally 7,819 units. Between 2013 and 2018, manufacturing and process automation had an average total turnover increase of 7% per year, compared to 2% in the manufacturing sector. According to recent data published by Confindustria, this is due to the decrease in national investments, influenced by a macroeconomic context considered to be more unstable, and the absence of previous subsidies.

Benefits of automation in welding field

According to data published in 2018, handling is the predominant field of application in our country, with 76% of total consumption. Welding is growing slightly, at around 10%, while assembly takes a percentage of 8.8%. The use of automation in industrial welding plants becomes a basic technological solution that aims to significantly increase productivity and competitiveness between companies. The higher the number of parts to be produced, the lower is the calculated depreciation rate. Large companies have been very supportive of the introduction of automation, but a decisive boost is expected from SMEs. Companies that already adopt automated solutions are known to be more favourable to the use of robotics (75% against 47%).

It is recognized that automated welding produces high quality and repeatable joints while reducing heat production, slags and, wastes during the process. The use of a welding robot avoids oversized joints, since the current systems are programmed with parameters that allow to joint production with precise dimensional characteristics, avoiding expansion or contraction processes in the surrounding metal during heating and cooling cycles.

Automated systems guarantee high reproducibility and shorter cycle times in welding processes, reducing the consumption of resources and electricity compared to manual processes, thus meeting the growing need for energy efficiency. The speed of the machines is about five times higher than the average man, not to mention that the robot can move quickly from one joint to the next, allowing the execution of several operations in series.

Automation reduces labour costs and compensates for the shortage of skilled welders, as less practice is required. Therefore, the welder becomes a process monitoring operator.

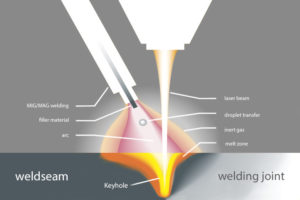

Flexibility also extends to the variety of process types and joints that can be manufactured based on a variety of materials and components. Generally speaking, the robotic stations are equipped with a repository with various welding programs that can be used on different materials and thicknesses, for example MIG, MAG and TIG. Here it is possible to install standard robots, hollow wrist robots, robots with push-pull torch or with master-slave system.

“Cobotized” welding

In particular, it is worth mentioning how welding benefits considerably from the use of collaborative robots (cobots), which carry out the tasks alongside the operators in the assembly lines. Cobots represent less than 3%, but estimates indicate average annual growth of more than 50% until 2022. While large companies are mainly interested in installing fast-working robots in their production lines in order to maximize productivity, the cobots are more suited to the needs of small and medium-sized companies. They are slower and more flexible since they have to learn, repeat, and save movements to be carried out from the operator. . In essence, the robotic arm is able to replicate, the work that a highly qualified welder would do with greater quality and in less time, implying additional health and safety benefits.

Welding requires repetitive and precise torch movements. As such, the welder’s fatigue is not an inconsiderable problem. This physical condition can lead to musculoskeletal disorders. By placing a robotic arm next to the human, fatigue is drastically reduced as the torch is manipulated by the cobot. The welders are only required to monitor the process and guide the torch where necessary. The ergonomics of the working environment is considerably improved, since the use of robots allows to avoid welding in forced positions. This prevents stress to the operator’s body and limbs experienced during manual work and risky for their health.

Carrying out the operation with the help of a robot protects the operators’ health, preventing them from being exposed to the UV light generated by arc welding, which can cause visual disorders, as well as long-term carcinogenic pathologies generated by continuous exposure to smoke and toxic gases. In particular, the use of collaborative robots allows better control of emissions, thereby reducing the environmental impact.

There are considerable benefits in terms of joint quality, since the use of a robotic arm guarantees a defect rate of less than 3%, avoiding additional work processes. It is not necessary for the operator to act manually to file or roughen the beads released from the welding material or to repeat the work, using a gas torch if any defects have to be eliminated. The cobots’ precision combined with optimized welding power avoids the use of additional welding wire which causes energy and material waste. By reducing the quantity of defects and using adequate power, the use of a cobot allows to considerably reduce the consumption of gas to maintain the flame active. CO2 emissions into the environment are lower. In this regard, it should be noted that welding accounts for 4.5% of the European Union’s gross energy consumption, and arc welding produces 9.82 grams of CO2 per second.